Turning Japanese

Or English , American etc. Depending on what countryyour bike comes from!

Does your shed need a lathe?

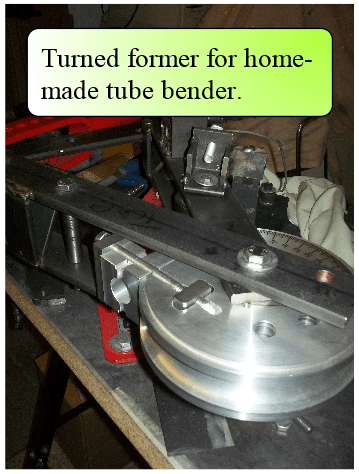

Well that really depends on how involved you want to get with your bike building. If you’re just into maintaining and restoring a fairly standard bike, then no, you probably don’t need a lathe. But, once you start wanting to mix and match parts of different bikes together, to line the wheels up, to get the chain run correct, to get brake calipers central to their discs etc. Being able to pop to the lathe and quickly turn something up is a huge bonus. Then there’s the more involved stuff. You can now start making your own foot pegs, paddock stand bobbins, crash bungs, wheel spindles, fasteners…

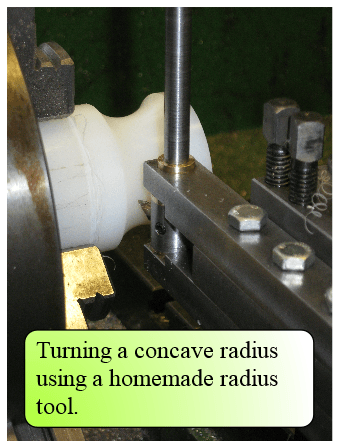

As well as basic turning, there are many more operations that can be performed on a lathe for example: taper turning, thread cutting, knurling, boring, drilling, filing, polishing and grinding. You can also do a bit of milling. The US Army publication : - “US Army Fundamentals of Machine Tools” gives a really good overview. A pdf copy is available on the website HERE. There are also publications here dealing with lathe operations, milling and metal properties. There’s some useful stuff in these. The formatting has gone awry in places when these were first converted to pdf, but I think you can get the gist. The first one is probably the best for starters, the others get quite detailed. Be aware that being American all the measurements are in inches (that may or may not be a problem for you!) there are also some design differences between the toolposts and tooling used on American and English lathes and the speeds and feeds calculations included are for industrial sized machines. They may not always be appropriate for small, hobby machines.

As well as basic turning, there are many more operations that can be performed on a lathe for example: taper turning, thread cutting, knurling, boring, drilling, filing, polishing and grinding. You can also do a bit of milling. The US Army publication : - “US Army Fundamentals of Machine Tools” gives a really good overview. A pdf copy is available on the website HERE. There are also publications here dealing with lathe operations, milling and metal properties. There’s some useful stuff in these. The formatting has gone awry in places when these were first converted to pdf, but I think you can get the gist. The first one is probably the best for starters, the others get quite detailed. Be aware that being American all the measurements are in inches (that may or may not be a problem for you!) there are also some design differences between the toolposts and tooling used on American and English lathes and the speeds and feeds calculations included are for industrial sized machines. They may not always be appropriate for small, hobby machines.

Ok, I’m convinced, what lathe should I buy?

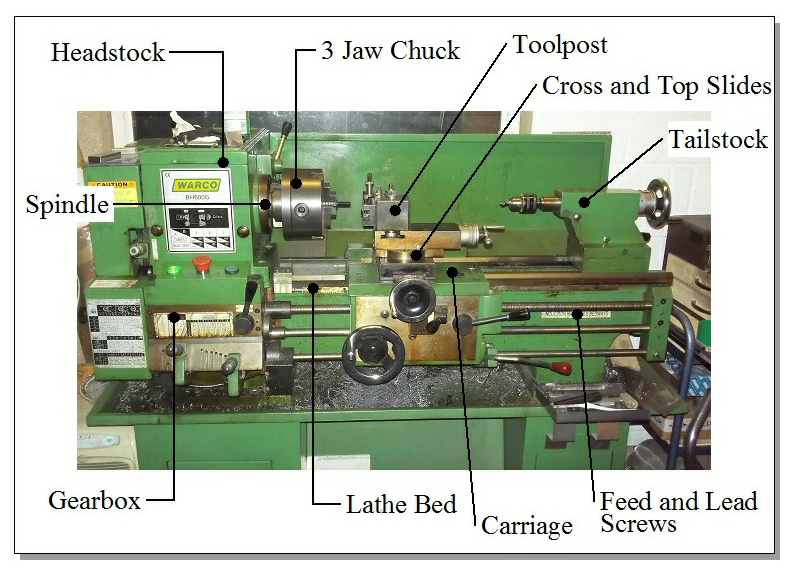

Typically, the answer would be the biggest that you can afford and have room for. That way you’re less likely to run out of capacity. The size of a lathe is usually specified by it’s centre height and distance between centres. Centre height is the distance between the centre of the lathe spindle and the top of the lathe bed. It may also be specified as swing over bed or just swing, this is the largest diameter bit of metal that can be rotated over the bed of the lathe. Distance between centres is the distance between a centre held in the spindle nose and a centre held in the tailstock. Obviously, the bigger these numbers are; the bigger bits of metal you can machine.

The lathe in the pictured below is a Warco BH600. It has a 12” (300mm) swing with 24” (610mm) between centres. It is also of Far Eastern origin, but guess what, it’s been working perfectly for the last 12 years. Don’t instantly dismiss everything that’s made in China, but do check out the company that’s acting as the importer. Make sure any spares you may need are readily available and that appropriate QC checks are in place.

The lathe in the pictured below is a Warco BH600. It has a 12” (300mm) swing with 24” (610mm) between centres. It is also of Far Eastern origin, but guess what, it’s been working perfectly for the last 12 years. Don’t instantly dismiss everything that’s made in China, but do check out the company that’s acting as the importer. Make sure any spares you may need are readily available and that appropriate QC checks are in place.

The choice you have will be between an industrial sized lathe: Colchester, Harrison, Myford etc. Or a lathe aimed at model engineers: Warco, Emco, Chester, Wabeco and Myford again. If you have the space, then a used industrial lathe can be a good buy, but be aware that these will probably have 3 phase electrics. You can’t just plug this into a 3 pin socket, unless you’re lucky enough to have a 3 phase supply. You will have to either change the three phase motor to a single phase one, or invest in a single phase to three phase convertor.

Lathes aimed at model engineers are usually designed to be plug and play with domestic electrical supplies. Attending the larger model engineering shows will allow you to see these machines up close. Whatever route you choose, a lathe supplied with a good range of accessories is preferable. Chucks, faceplates and tooling are expensive to buy individually, so try and negotiate a good package deal

Lathes aimed at model engineers are usually designed to be plug and play with domestic electrical supplies. Attending the larger model engineering shows will allow you to see these machines up close. Whatever route you choose, a lathe supplied with a good range of accessories is preferable. Chucks, faceplates and tooling are expensive to buy individually, so try and negotiate a good package deal