April 2018

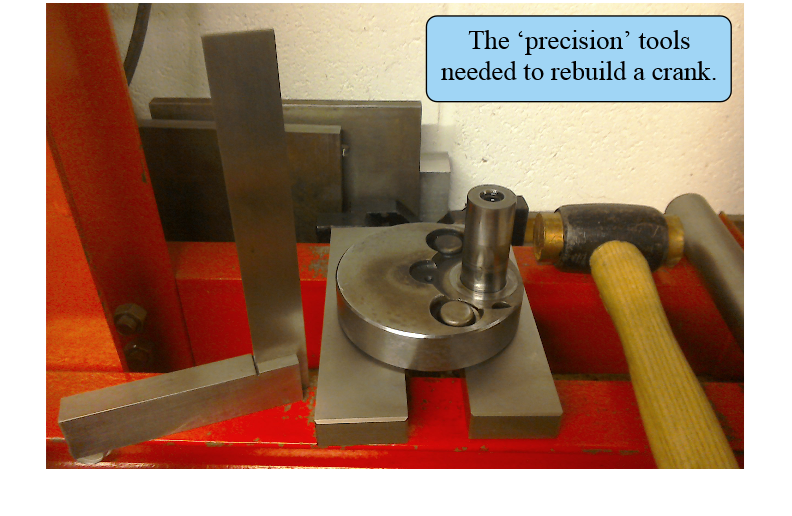

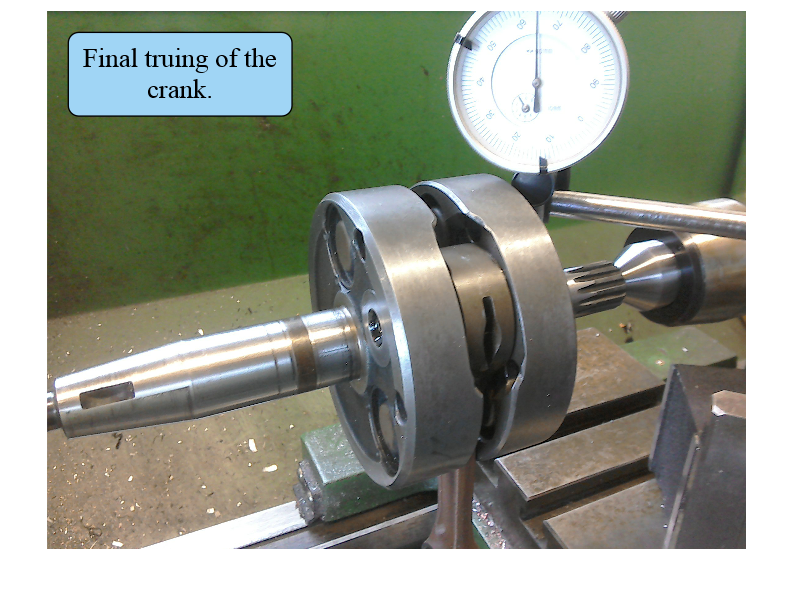

There are some jobs on your bike that you know need to be done, but you put off doing for various reasons. For me, it was rebuilding the pressed together crank of a two-stroke dirt bike. I could have just send it out to be done, but it was something that I really wanted to try. It was just the thought of trying to reach 0.05mm tolerances using a hydraulic press and a large copper mallet (hardly precision tools) that seemed impossible. I watched numerous Youtube videos on how it should be done, but most used a proper jig - far too expensive to buy and far too time consuming to make, especially since this is only the second time in 20+ years of bike ownership that I’d needed to rebuild a crank.

I knew that it had been successfully done for many, many years without the aid of fancy jigs, so there must be some information about doing it the old school way out there somewhere. Google searches eventually found a couple of useful links, from

Alpha Crank Reconditioning and if you’re ever attempting a Kawasaki H1 or similar try

THIS.

Armed with these, the info I’d gained from Youtube and a knackered crank that I’d bought cheaply to practise on, I gave it a go. Guess what, it was much easier to do than I thought. Time consuming, yes, but with patience it was perfectly do-able. After a couple of practise goes with the old crank, I felt able to do it for real, and it all worked out OK. Don’t know what I’d been worried about!

See the full write up on the crank rebuild in a future issue of ‘Offbeat Bikes’ magazine.

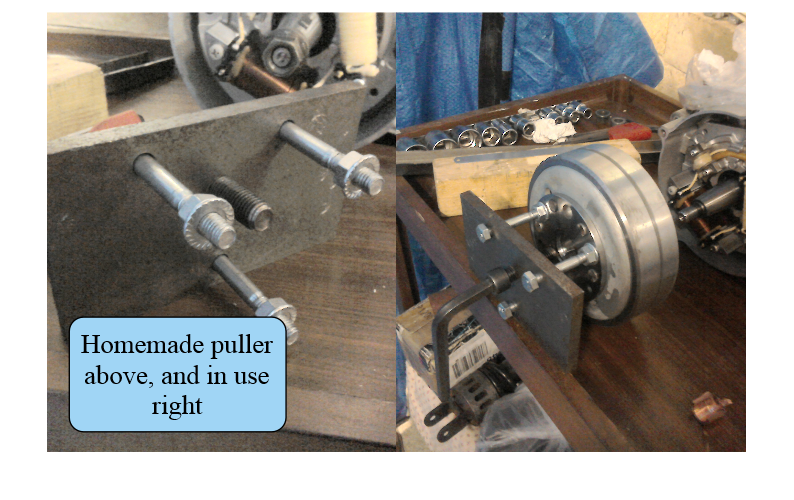

Several weeks ago, the Monday topic was tools, which brands were the best buys etc. But when it comes to special tools, especially model specific tools, then your choice is limited. Usually, you buy the manufacturer’s special tool, or you improvise your own. The rather crude (but effective) flywheel puller shown below, replaces a Yamaha special tool with a retail price of £140!

Below, is a homemade crankshaft installation tool. Now, you can manage without one of these. You can get around needing one by leaving the crankshaft in the freezer for a couple of hours, and heating the main bearing that it needs to fit in. Hopefully with the bearing expanded and the crankshaft contracted, the two should slide together easily. If you have the installation tool though, you don’t have to worry about the heating an cooling stuff: you just set it all up, and carefully, by tightening the nut on the top, draw the crankshaft into place. I made this one out of scraps lying around the garage and it really does make the process of getting the crank installed less fraught. You could, of course, buy the special Yamaha tool to do the job - that’ll be £130 please! So it really does pay to be able to improvise your own.

Haynes manuals are usually quite good for suggesting work-arounds when special tools are called for. Searching bike specific forums can also turn up designs for homemade tools. Failing that, if you can get a look at the manufacturer’s tool, even if only in pictures on the internet, you can often come up with your own solution. For cases where you’re really stuck, owner’s clubs sometimes have special tools that can be hired by club members.

A slighty different blog post this week. This is the story of a Royal Enfield bobber build, from start to finish. You can read this online via Yumpu by clicking the following

LINK or download a pdf version by clicking

HERE. Please note, the original issue was designed to be viewed double page (magazine style) unfortunately depending on what device etc. you're viewing on, you may only be able to get it in single page format.